Products

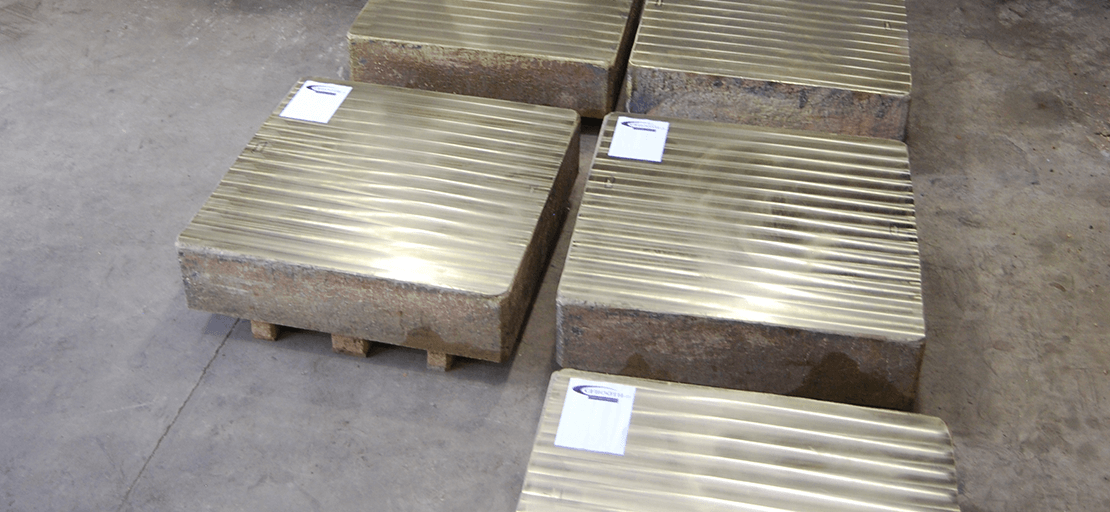

CF Booth can supply products in a variety of different forms, all of which originate through our permanent mould casting process using modern sophisticated electric induction furnaces providing optimum metal recovery, material is then cast into a specific sized mould relating to the finished size required.

Thereafter material can be proof machined to size or transferred onto an appropriate hot working process such as forging and heat treatment to provide a continuous and refined grain structure throughout, which in turn will improve the materials strength characteristics.

We have the extensive capabilities to manage your project from start to finish, providing key attention to detail monitoring every step of the manufacturing process. We offer material in the forms mentioned below.

Dye Penetrant Testing

We offer a Dye Penetrant service which is a process that uses penetrating liquids containing dyes or fluorescent substances to ensure material is free of any surface irregularities, further ensuring product conformity.

This operation is most commonly used as standard on finish machined components which are to be used in safety critical applications.

Key practices

Ultrasonic Testing

Approximately 98% of our wrought material is subjected to Ultrasonic examination in its machined condition, even though at times our customers do not request this.

We value our reputation greatly as a major supplier of wrought copper alloy based material which is why we take the extra measure to ensure that all our parts conform to the relevant material and Ultrasonic testing specifications.